Did you know that one cotton shirt uses about 3,000 liters of water to make it?

Clothing production consumes a lot of resources, from cotton cultivation to textile processing—it’s a high-energy operation. Textiles, on the other hand, account for around a quarter of all chemical substances produced worldwide.

Traces of these chemicals can be found in our waterways, ranging from streams, seas, oceans to the water we drink.

There are wasteful applications of valuable commodities such as water and electricity. That is why a natural approach is required that would transform the way clothes are manufactured.

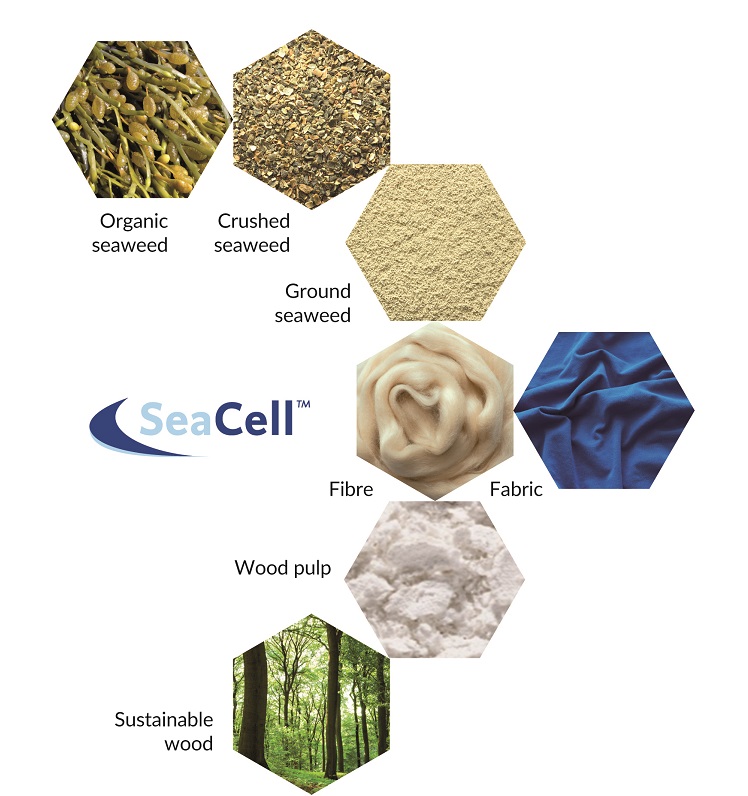

C-FIBER™ is one such trademark technology of Pangaia, which uses eucalyptus pulp from the Earth and seaweed powder from the ocean to transform nature into cloth. This results in soft, silky styles that sustain the habitats used in their production and return to the earth what we take.

PANGAIA is a direct-to-consumer materials science company which is headquartered in London, England.

WHAT GOES IN C-FIBER?

SEAWEED

EUCALYPTUS PULP

Seaweed is a regenerative natural resource. It grows abundantly under the sea, necessitating the use of no freshwater during the growth stage. Pangaia sources their seaweed from Iceland every four years, allowing for complete recovery in between.

The eucalyptus pulp is processed into lyocell which is a biobased man-made fiber made using a closed-loop manufacturing method, which recycles water and reuses up to 99 percent of the solvents. This produces relatively little waste and produces a fiber that biodegrades in water, landfills, and composting. Eucalyptus embodies full circularity, starting and finishing in nature since it grows rapidly without irrigation or chemicals and can be cultivated on incredibly dry land.

Over-reliance on a single ingredient can harm the diversity in our ecosystems because a strong market for a single ‘ingredient’ encourages monocropping and monoculture plantations.

To help maintain the natural equilibrium, this innovative material is developed that offers back as much as it utilizes. C-FIBER™ is manufactured from plentiful plants that use ocean water and rainfall rather than limited freshwater supplies such as groundwater, surface water, etc, and it recycles elements from the manufacturing process to construct closed-loop processes.

PROPERTIES

In natural saltwater ocean habitat, seaweed grows abundantly and Eucalyptus can be cultivated on very dry land and grows rapidly without irrigation or pesticides. Both materials are made from green resources, and neither raw material requires additional freshwater to mature. Hence C-FIBER is water and energy-efficient.

The fabric is 100% biodegradable which means that after you’ve finished with it, it biodegrades in dirt, landfill, or water, returning to the Earth. This is the epitome of biological circularity.

So, all together it’s just as comfortable as your favorite t-shirt, but better for the planet..

REFERENCES: